(Even Though They’re Not Required in the U.S.)**

When you’re working with stranded or braided copper wire, the quality of your termination directly affects the reliability and safety of the entire circuit. That’s where wire ferrules come in — small components that make a big difference.

While ferrules are widely used and often required by electrical standards in Europe, they remain optional in the United States. But “optional” doesn’t mean unnecessary. When used correctly, ferrules can dramatically improve connection quality and reduce future maintenance issues — especially in control panels, equipment subject to vibration, or anywhere stranded wire is used.

This guide explains what ferrules are, why they matter, when they’re worth using, and the tools we recommend based on real experience in the field.

What Is a Ferrule?

A ferrule is a small, thin metal sleeve (usually tin-plated copper) that slides over the stripped end of stranded copper wire. Once positioned, the ferrule is crimped with a specialized tool, compressing all the strands into a unified, solid termination.

A proper crimp:

- Prevents stray strands from splaying

- Creates uniform electrical contact

- Improves mechanical strength

- Reduces oxidation between strands

- Makes the wire behave like a solid conductor inside the terminal

Ferrules often include a collar or flared opening to guide the wire into the tube, helping ensure clean, consistent insertion.

Why You Should Use Ferrules (Even When Code Doesn’t Require It)

1. More Reliable and Consistent Connections

Stranded wire is flexible and durable — but those same characteristics make it harder to terminate cleanly. With bare strands:

- A terminal screw can miss some strands

- The wire can spread under pressure

- Uneven contact can create resistance

- Loose strands can lead to overheating or arcing

A ferrule eliminates all of these risks by compressing the strands into one uniform cylinder that seats cleanly into the terminal.

2. Better Safety & Fewer Short-Circuit Risks

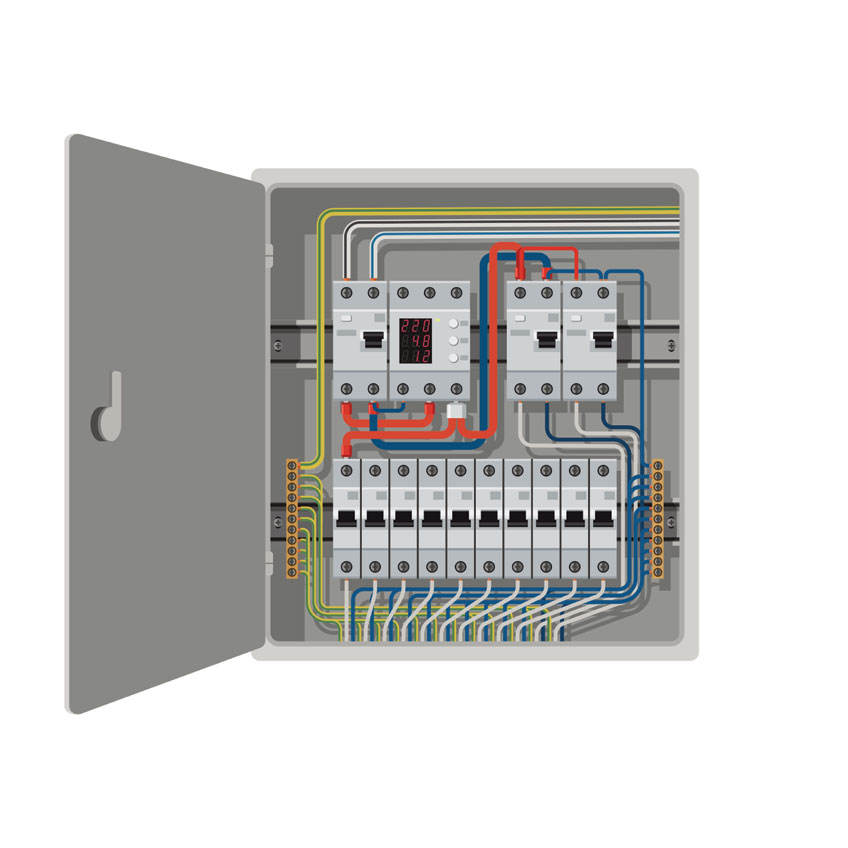

In control panels or junction boxes where conductors run close together, stray wire strands create a real risk of accidental contact. Ferrules ensure everything stays contained.

A well-crimped ferrule also forms a gas-tight connection, reducing air gaps where moisture or oxidation can build up and weaken the conductor over time.

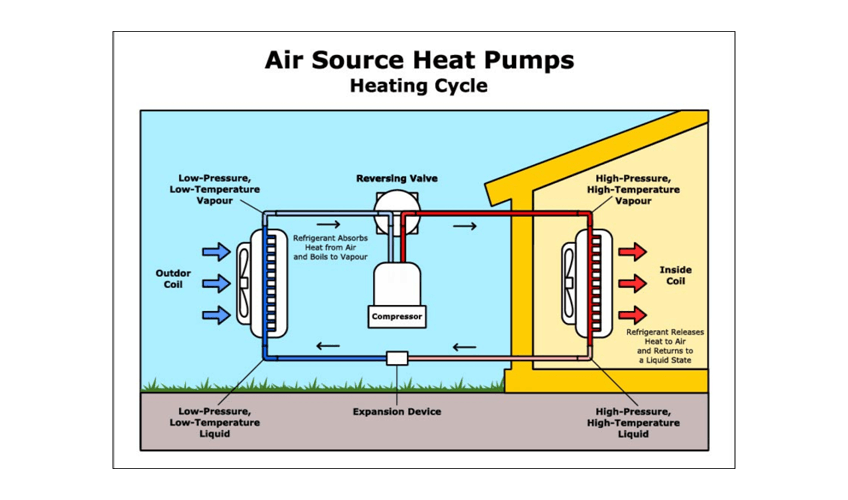

3. Superior Performance Under Vibration

If your installation is affected by vibration (HVAC units, motors, pumps, machine equipment, etc.), ferrules dramatically reduce loosening over time. They stabilize the termination and help the connection maintain consistent contact pressure.

4. Cleaner, More Professional Wiring Work

Especially inside busy control cabinets or contractor-facing projects, ferrules provide:

- Cleaner terminal entries

- Faster reconnections

- Easier troubleshooting

- Better long-term durability

A ferrule-terminated conductor is simple to insert and remove without fraying or breaking strands.

5. A Best Practice in Europe — and Growing in the U.S.

European standards often require ferrules on stranded wire for equipment certification.

While the U.S. does not mandate ferrules, many electricians and panel builders treat them as best practice, especially in environments requiring high reliability.

When Ferrules Make the Most Sense

Ferrules are particularly beneficial in:

- Control panels and terminal blocks

- HVAC systems and rooftop units

- Industrial machines or vibration-heavy environments

- Home automation systems and low-voltage wiring

- Any installation where wires will be removed and reinserted

If you’re using stranded or braided copper wire, ferrules almost always improve connection performance.

How to Use Ferrules Correctly (Best Practices)

-

Use ferrules only on stranded wire

They’re not intended for solid conductors. -

Select the correct ferrule size

Most ferrules use color-coding to match AWG / mm² gauge. -

Strip only the necessary insulation length

You want the conductor fully inside the metal tube, but not exposed. -

Insert the wire fully into the ferrule collar

Ensure no strands are flared or misaligned. -

Use a proper ferrule crimping tool

Avoid pliers or makeshift tools — they can produce weak crimps.

⭐ Our Recommended Tool: The Wiha Ferrule Crimper

After testing multiple crimping tools over the years, our favorite by far is the Wiha ferrule crimper.

We’ve found that the Wiha tool provides:

- Consistent, high-pressure, gas-tight crimps

- Smooth operation and comfortable ergonomics

- Excellent performance across a wide ferrule size range

- Durable construction that holds up under daily professional use

There are many ways to crimp a ferrule, but if you want a reliable, professional tool that performs well job after job, Wiha is the crimper we reach for every time.

Ferrules: A Small Upgrade With Big Long-Term Payoffs

While ferrules may be optional in the United States, their benefits are undeniable:

- Cleaner, safer terminations

- Better reliability

- Reduced risk of failure

- Improved performance in vibration-prone environments

At Allstar Electrical, we believe in doing work that lasts — and ferrules are one of those small details that elevate a wiring job from “acceptable” to exceptional.

If you ever see stranded wire in your project, consider using a ferrule. You’ll avoid problems later, and your connections will thank you.

.jpg)